Industrial foam seal solutions are specialized sealing materials made from foam to provide protection, insulation, and cushioning in various industrial applications. These seals are used to prevent the entry of air, water, dust, and other contaminants while also reducing noise and vibration.

Industrial foam seal solutions provide sealing, insulation, and protection in various industries. They prevent leaks, reduce noise, and improve durability.

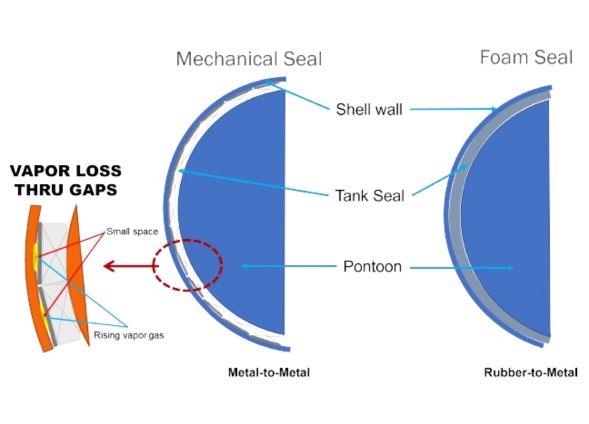

Foam seals fill gaps to create airtight or watertight barriers, preventing the entry of air, water, dust, and other contaminants, while also minimizing the loss of valuable product in the form of vapor.

Foam materials are compressible and can adapt to uneven surfaces.

High-quality formulated materials are used to withstand environmental challenges such as extreme temperatures, UV exposure, chemicals, and mechanical wear

Specially designed to minimize vapor formation and eliminate the use of metal components, reducing the risk of sparks that could lead to rim seal fire incidents.

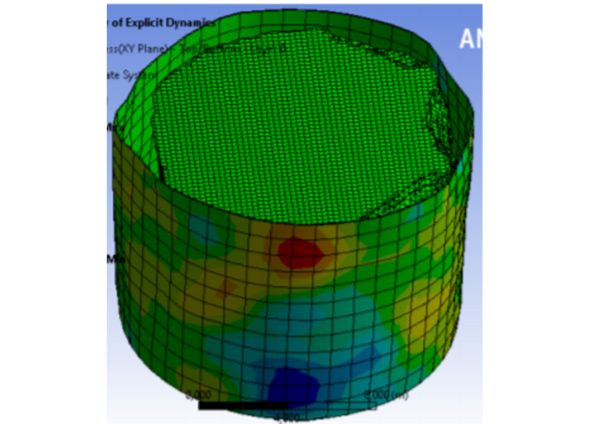

Sakura’s advanced R&D enables the creation of durable, high-performance sealing materials. Each product undergoes rigorous testing before market release.

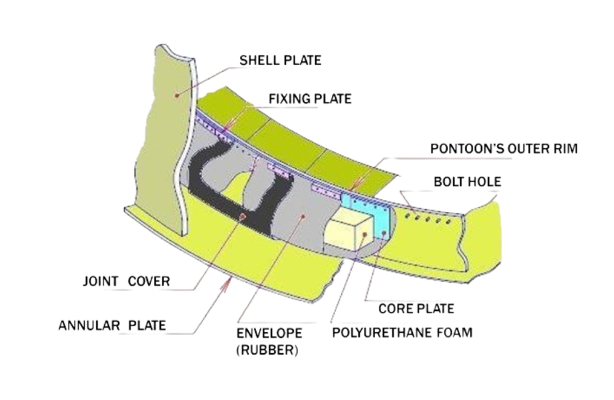

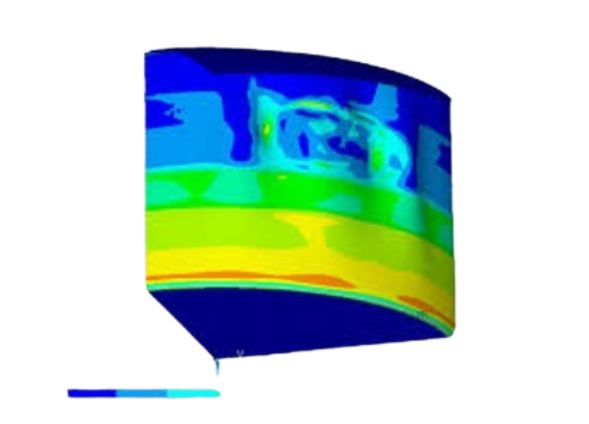

Polyurethane foam flexibility absorbs forces from pontoon shifts, internal mixing, elevation changes, and wind—protecting the tank structure from stress.

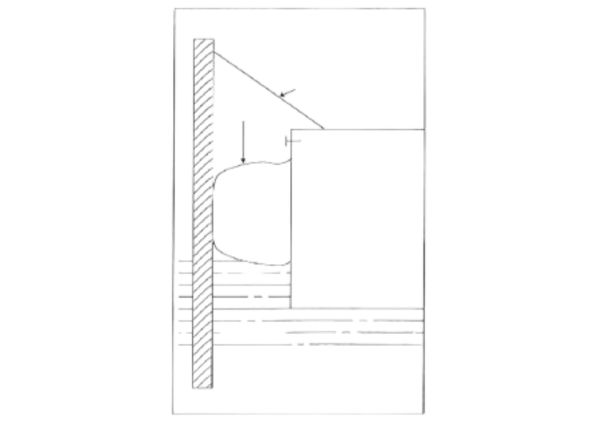

Tanks often deform or have weld lines—Sakura foam seals adapt to these irregularities with flexible polyurethane foam and a rubber envelope that maintains a consistent seal.

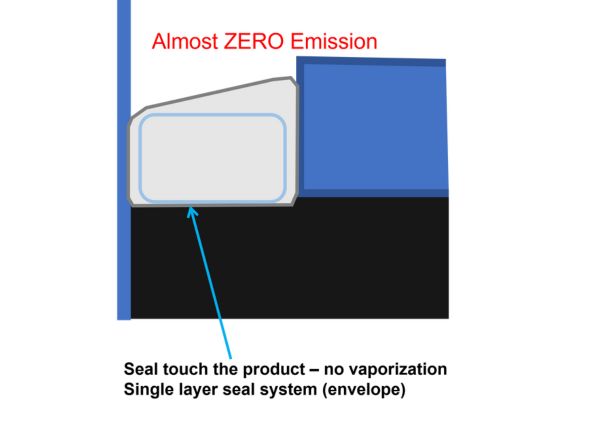

Rubber-to-metal sealing creates tighter contact than metal-to-metal, significantly reducing vapour emissions through gaps.

The foam seal is designed to contact the liquid surface directly, effectively reducing vaporisation—and therefore emission. This setup often eliminates the need for a secondary seal.

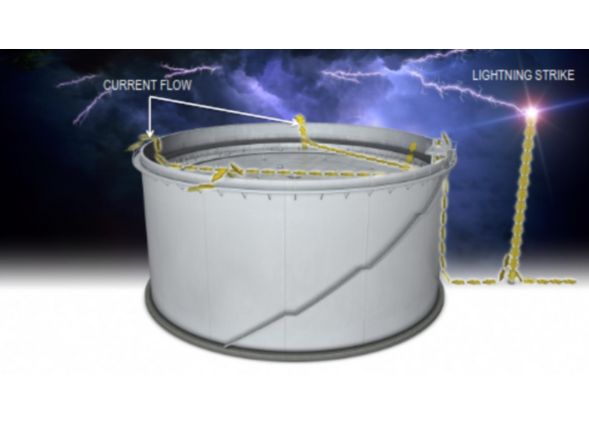

The foam seal prevents vapour congestion and is made from insulating materials, greatly reducing the risk of sparks or fires. It also offers protection against lightning—one of the leading causes of tank fires.

Formulated with soft, high-performance materials that resist corrosion, deformation, harsh weather, and aromatic exposure.

Sakura foam seals feature a straightforward design with minimal parts, reducing the risk of malfunction and ensuring reliable performance.

Thanks to its simple design and minimal components, Sakura foam seals can be installed within days—not weeks.

| material *1 | aromatic resistance | main composition | service |

|---|---|---|---|

| S-100 | 100% Max | Fluoroelastomer (FKM) | Benzene, Toluene, Xylene, etc |

| S-70 | 70% Max | NBR *2 | Crude Oil, Naphtha, Kerosine, Gasoline, etc |

| S-50 | 50% Max | ||

| S-40 | 40% Max | ||

| S-40E | Crude Oil, Naphtha, Kerosine, Gasoline, ETBE+Aromatic, etc |

||

| MS-1 | — | Methanol, ETBE 100%, etc | |

| AD-1 | EPDM | Methanol, Ketones, etc |

An external floating roof tank (EFRT) is a type of storage tank featuring a roof that floats on the liquid surface and moves with the liquid level, with the roof exposed to extreme weather conditions

An internal floating roof tank is a fixed-roof storage tank with a floating deck or pan installed inside, directly on the surface of the stored liquid. Since it is enclosed by a fixed outer roof, the internal floating roof is shielded from external weather conditions.

WhatsApp us