Sakura Foam Seal

Innovative Foam Seal Design

Eliminating The Risk Of Fire Incidents

Floating roof tank seals are an integral part of aboveground storage tanks used for storing liquids, particularly petroleum products like crude oil or refined fuels. These seals serve several important functions:

Preventing Evaporation: Floating roof tanks have a floating roof that moves up and down with the level of the stored liquid. This floating roof reduces the vapor space above the liquid, which helps prevent evaporation loss of volatile liquids.

Environmental Protection: By reducing evaporation, these seals help minimize emissions of volatile organic compounds (VOCs) into the atmosphere, contributing to environmental protection and regulatory compliance.

Product Quality: Minimizing evaporation also helps to maintain the quality of the stored product by reducing exposure to air and moisture.

Safety: Seals help reduce the risk of fires or explosions by minimizing the presence of flammable vapors in the tank’s vapor space.

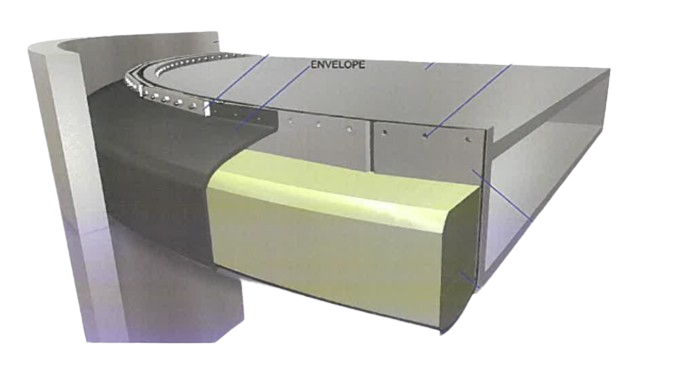

Sakura floating roof tank foam seals utilized special formulated rubber envelope with polyurethane foam inside it to provide the sealings. The design prevented fire risks and reduce vaporisation and product emissions.

How It All Begin?

Designed Out Of Necessity

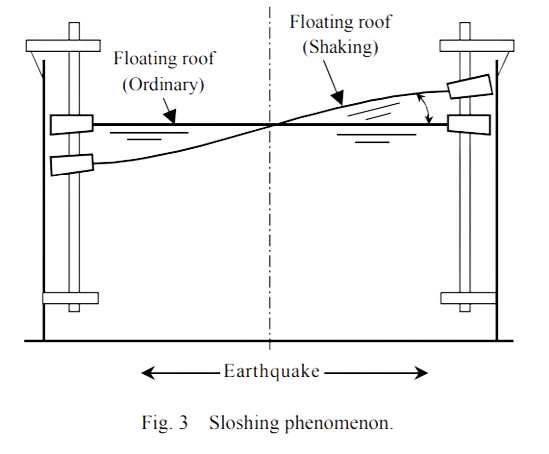

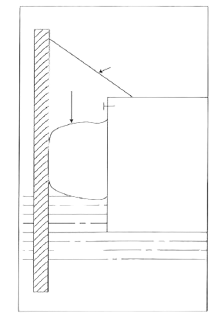

During the Niigata earthquake on June 16th, 1964, 5 crude oil storage tanks in a refinery caught fire and continued burning for two weeks, spreading into the surrounding area and burning down a total of 286 adjacent houses.

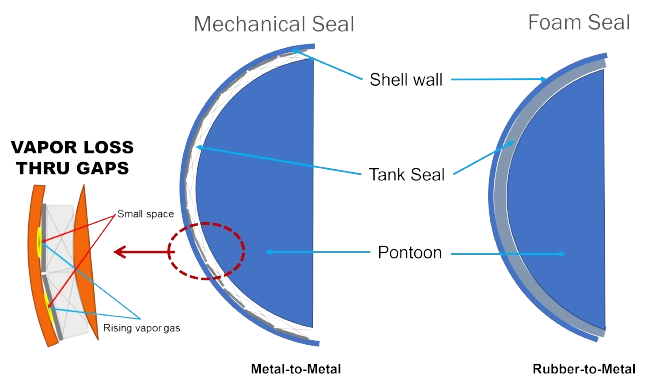

In order to avoid similar catastrophes from happening, studies were conducted to identify the root cause. It was identified that the sloshing phenomenon and the sparks generated by the metal touch sealing between the floating roof and the side wall ignited the fire.

Main counter-measures taken were that, for all future tank construction, the metallic seal mechanism was eliminated entirely and the side wall was heightened to prevent the outflow of oil.

Since then there was no case of tank fires reported in Japan even with regular earthquake incidents.

Source: AKATSUKA, Hirotaka (High Pressure Gas Safety Institute of Japan) KOBAYASHI, Hideo (Yokohama National University)

Sakura Foam Seals

Features & Benefits

Specially Formulated Rubber Materials

Sakura strong research and development enable them to formulate special materials that are not only durable but provide high sealing capability. The products undergo rigorous testing before introduce into the market.

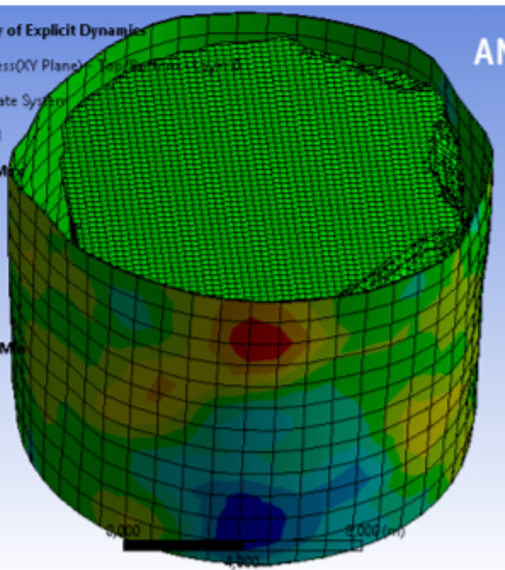

Absorb Unpredictable Forces and Tank Movement

Unpredictable movement of pontoon and elevation, current flow by internal mixer and wind affect tank wall movement.

The flexibility of polyurethane foam absorbs these unpredictable forces and movement.

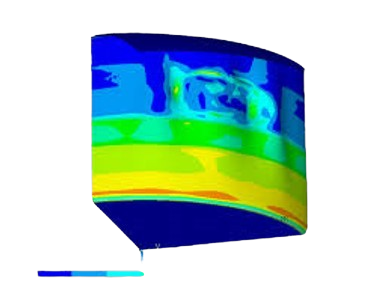

Accommodate Irregular Surfaces

It is normal for tank to deform and has weld line on its surfaces.

The weld line and tank shell deformation should not be a problem with a foam seal system as the flexibility of polyurethane foam and rubber envelop follows these irregular surfaces.

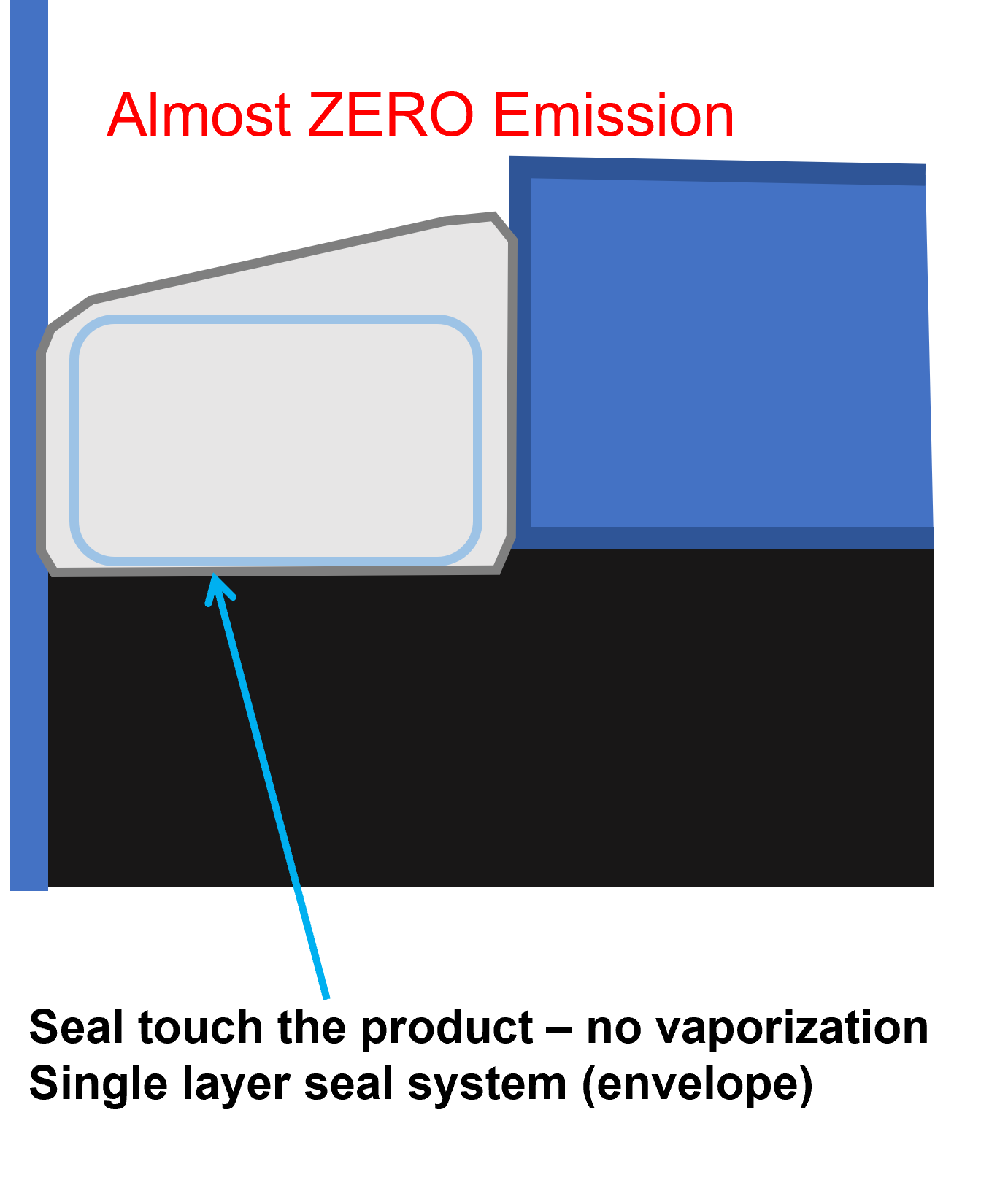

Minimise Emission

Compared to metal to metal sealing, the rubber to metal sealing has less gap in between them, thus minimise the product vapour emission through the gap.

Minimise Vaporisation

The foam seal system was set up in such as way that the seal will touch the liquid product which hinder the product vaporisation. As such, no vaporisation means no emission.

Consequently, it is not mandatory to have secondary seal in the foam seal system.

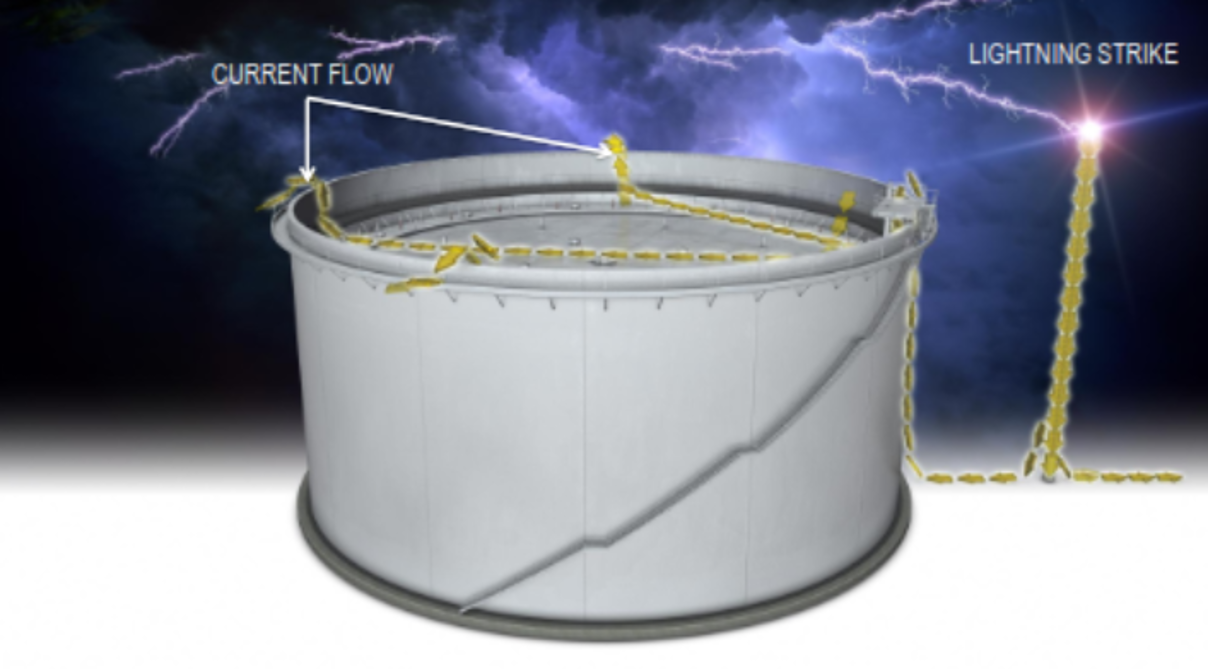

Minimise Risk of Sparks & Fires

Chances of sparks and fires is almost zero because there is no vapour congestions around seal. Furthermore, the seals are made of insulating materials that prevent any spark to occur.

Consequently, foam seal system will not be affected by lightning occurring within the area. This is significant as lightning was identified as the main contributor to tank fires.

No Corrosion & Deformation

Special formulated soft material for anti corrosion, anti deformation, weather resistance and aromatic resistance

Simple Design & Structure

Sakura foam seals system is simple using minimal parts, thus, reduce potential malfunction.

Fast Installation

Due to its simple structure dan design, the installation can be completed in a matter of days instead of weeks.

Sakura is the pioneer of tank seal and has been selling since 1950s in Japan. It has long and safe track record i.e. zero accident operation on the back of 3000++ tanks installation worldwide.

The achievement is made possible because of its high quality product under strict Japanese Manufacturing Standard, meeting aerospace industry requirement, as Sakura also supplied parts to aircraft industry.