Fine filtration using offline filter is essential in industries where machinery and engine reliability are critical.

Why Fine Filtration?

You may wanted to know why you should insist on fine filtration and the 7 reasons below should provide strong justification:

1. Fine Filter Captures Microscopic Particles

90% oil particles smaller than 10 microns. These tiny particles can infiltrate machinery and cause significant damage.

2. Fine Filter Prevents Wear and Tear

Small particles can lodge between moving parts because the dynamic tolerance in most equipment is between 1-5 microns. Once there, they cause friction and subsequently increased heat.

3. Fine Filter Prevents Clogging

Fine particles can accumulate in small clearance of the oil passages and filters, leading to clogging. It will restrict oil flow and hinder proper lubrication and hence, decrease performance and cause catastrophic failures.

4. Fine Filter Minimizes Settling Time

Fine particles take longer to settle in oil, remaining suspended and causing more damage over time.

5. Fine Filter Reduces Surface Area Issues

Tiny particles have a greater surface area, leading to more chemical reactions that deplete additives, form emulsions, and create other problems in the oil.

6. Fine Filter Avoids Sharp Particle Damage

Crushed larger particles become many small, sharp-edged fragments that cause greater wear.

7. Fine Filter Maintains Optimal Viscosity

Fine particles can alter oil viscosity, compromising its function and effectiveness.

Benefits of Fine Filtration

Enhanced Efficiency and Productivity

By removing contaminants, fine filtration ensures optimal oil viscosity and cleanliness, leading to smoother operation and reduced friction.

Reduced Operational Costs

Prevents premature equipment failure, extending component life and reducing maintenance and repair expenses.

Lower Fuel and Energy Costs

Efficient machinery consumes less fuel and energy, resulting in significant cost savings.

Extended Equipment Life

Removes contaminants that cause wear, preserving machinery and reducing the need for replacements.

Real-World Impact Of Fine Filtration

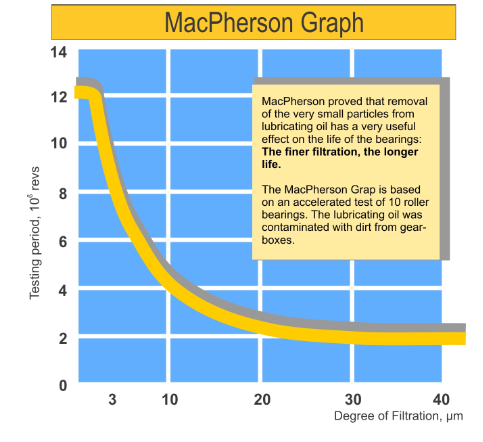

MacPherson’s testing shows that improving filtration from 30µm to 3µm can increase component life by 3-4 times. The impact will be that a usual 5-year bearing life becomes 20-year.

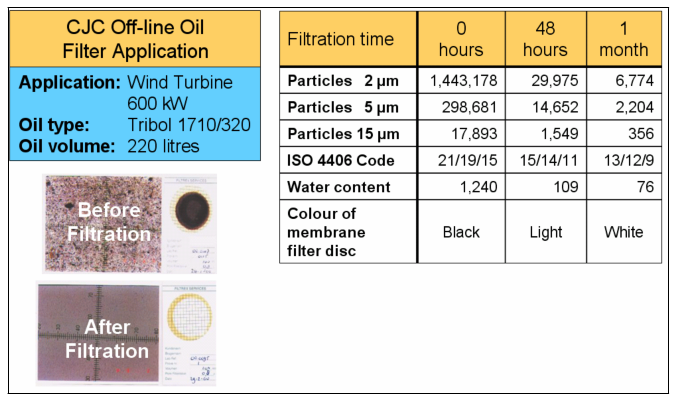

As the below example from wind turbine gear oil, one month after filtration, the particle contamination had drastically reduced from 21/19/15 to an ISO code of 13/12/9. The dramatic reduction of particle counts, extend bearing life approximately four times. CJC Fine Filter system was used in this case.

Conclusion

Fine filtration is crucial for modern industrial maintenance. It enhances performance, cuts costs, and extends equipment life, making it a vital tool for optimizing operations and achieving business success. As industries evolve, the importance of fine filtration will continue to grow, unlocking the full potential of machinery and engines.