Water contamination in oil is a critical issue in industries like automotive, manufacturing, and energy production. It occurs when water infiltrates lubricating, hydraulic, or other types of oils, leading to mechanical failures, reduced efficiency, and increased maintenance costs. Let us examine in details how water cause problems and how offline filter can help.

Why Water Contamination in Oil is a Concern

- Corrosion: Water leads to corrosion of metal components, causing premature wear.

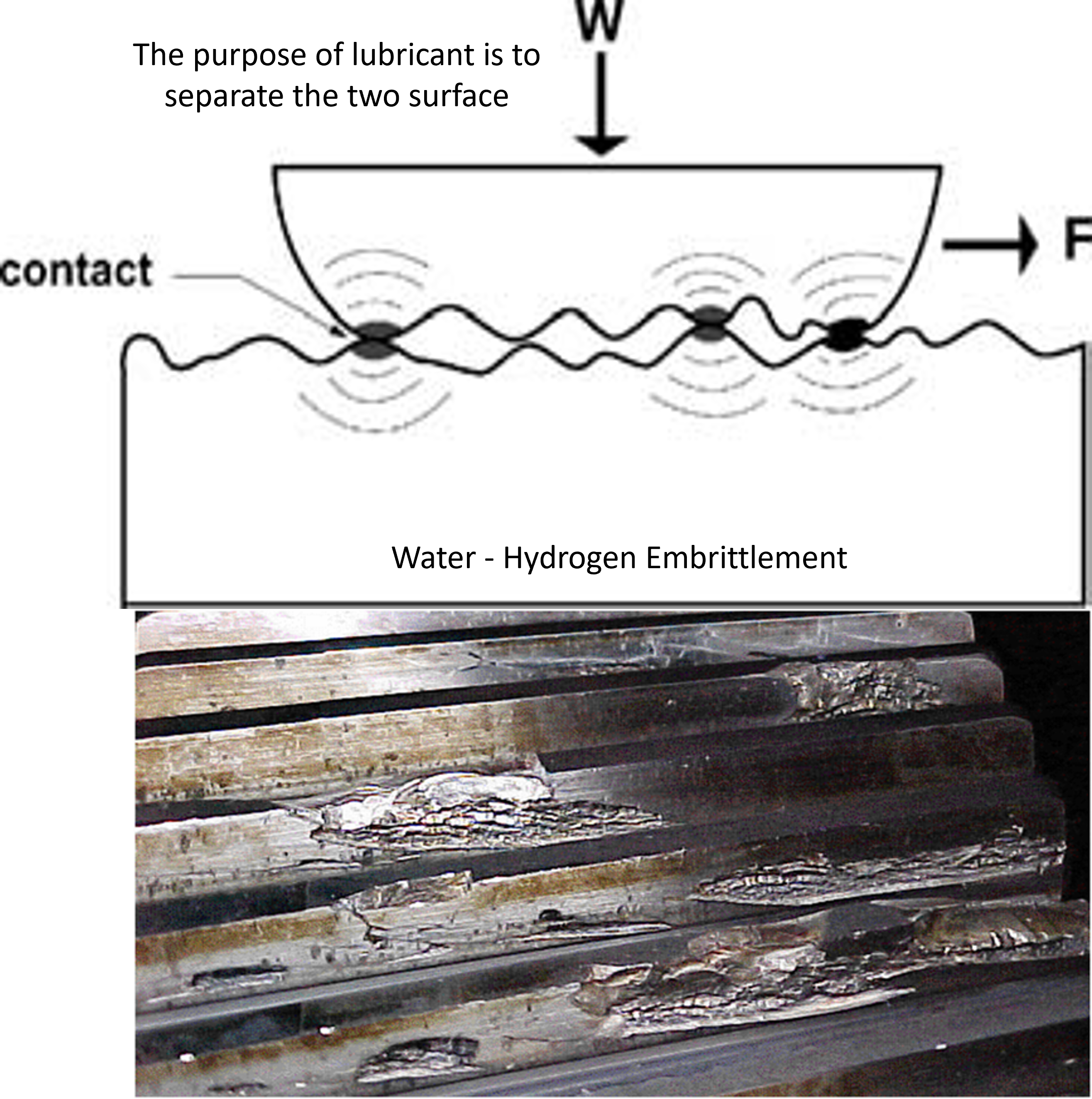

- Reduced Lubrication: Water decreases oil’s lubricating ability, increasing friction and wear.

- Oxidation: Water accelerates oil oxidation, forming sludge and varnish that clog filters.

- Microbial Growth: Water promotes microbial growth, producing harmful by-products.

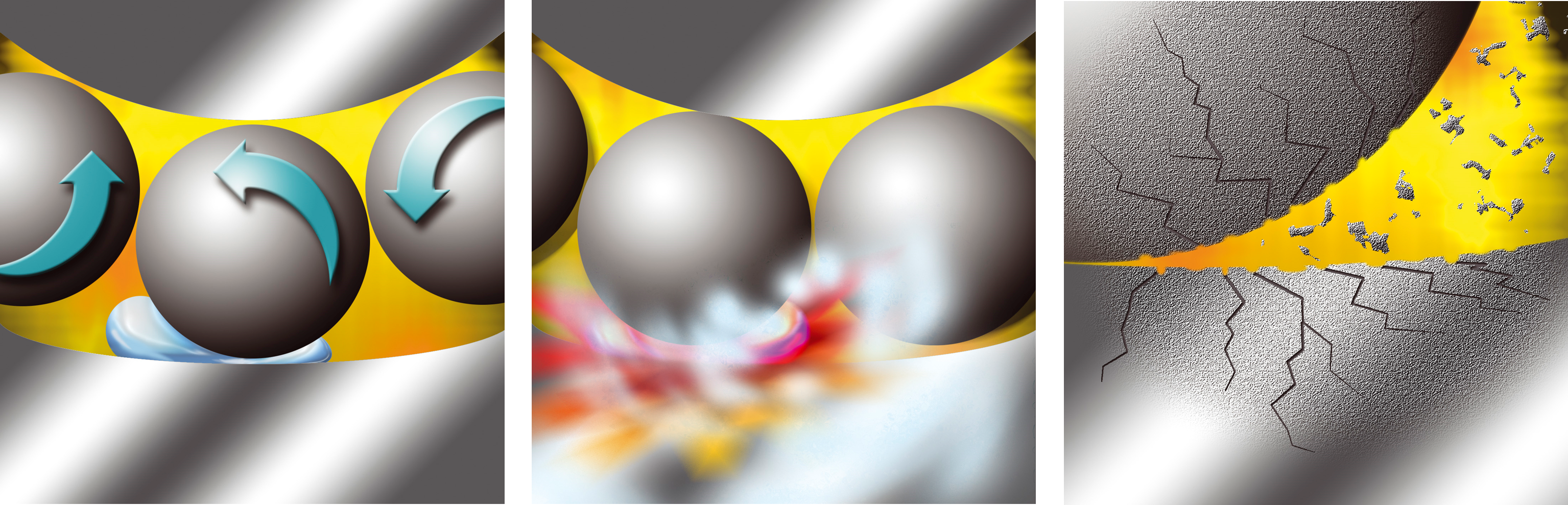

- Cavitation and Droplet Implosion: Water droplets form micro-bubbles that implode, causing shock waves and metal erosion.

- Hydrogen Embrittlement: Water can lead to hydrogen embrittlement, making metals brittle and prone to cracking.

Impact on Bearing Life

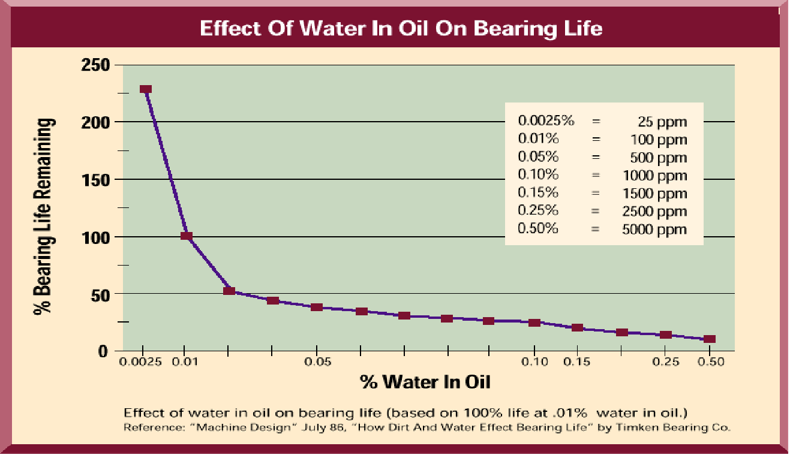

Bearings rely on high-quality oil for optimal performance and longevity. Water contamination can drastically reduce bearing life:

- Low Contamination (100-500 ppm): Bearing life can be reduced by up to 50%.

- Moderate Contamination (500-1000 ppm): Bearing life can be reduced by up to 90%.

- High Contamination (>1000 ppm): Bearing life can be reduced by more than 90%, with a high risk of catastrophic failure.

Effect on Oil Additives

Additives in lubricating oils enhance performance, but water contamination can deplete these additives:

- Additive Depletion: Water reacts with additives, reducing their effectiveness.

- Formation of Emulsions: Water forms emulsions, trapping additives and reducing their availability.

- Acid Formation: Water facilitates acid formation, degrading oil and additives.

- Increased Viscosity: Emulsions and sludge increase oil viscosity, reducing lubrication effectiveness.

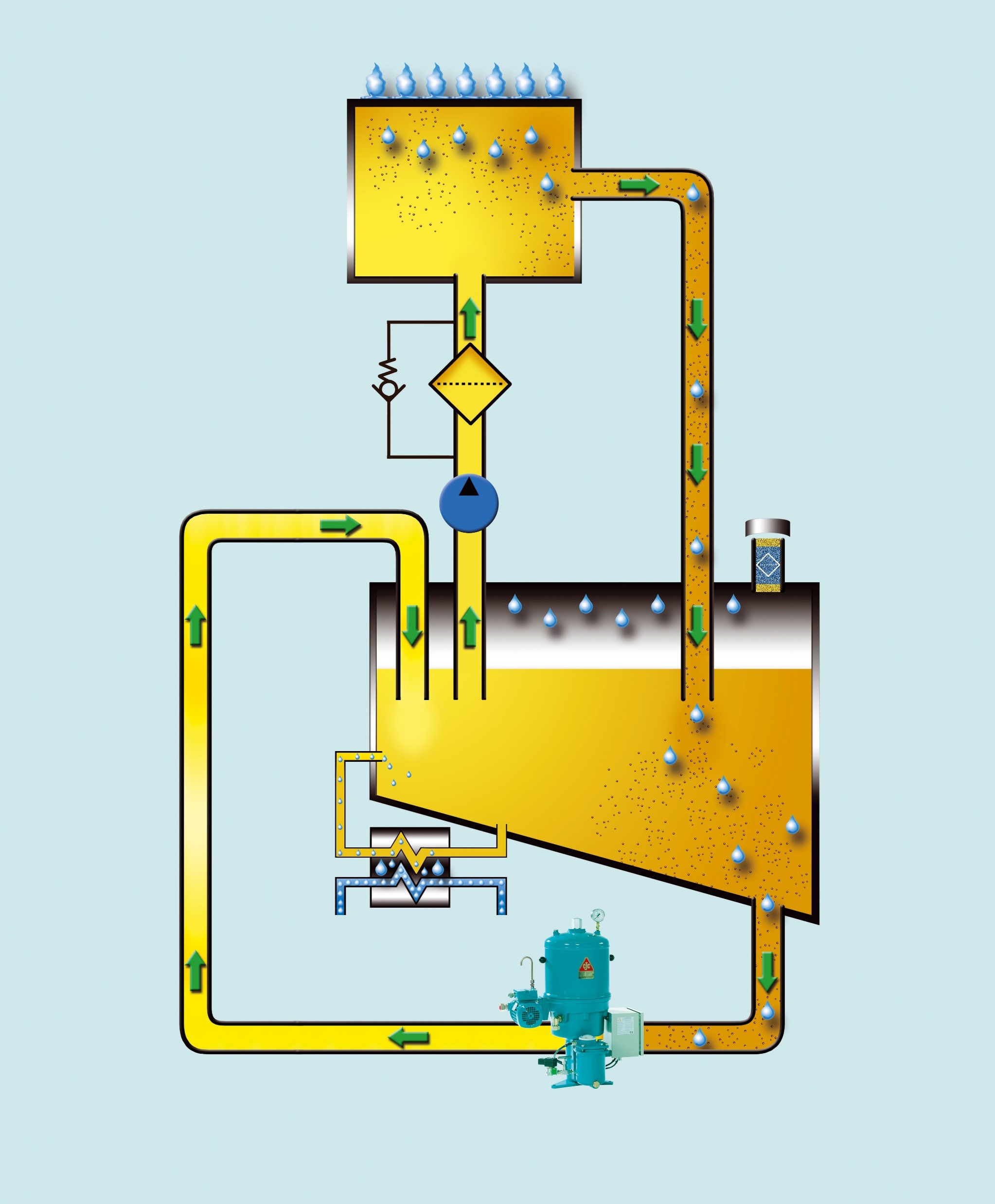

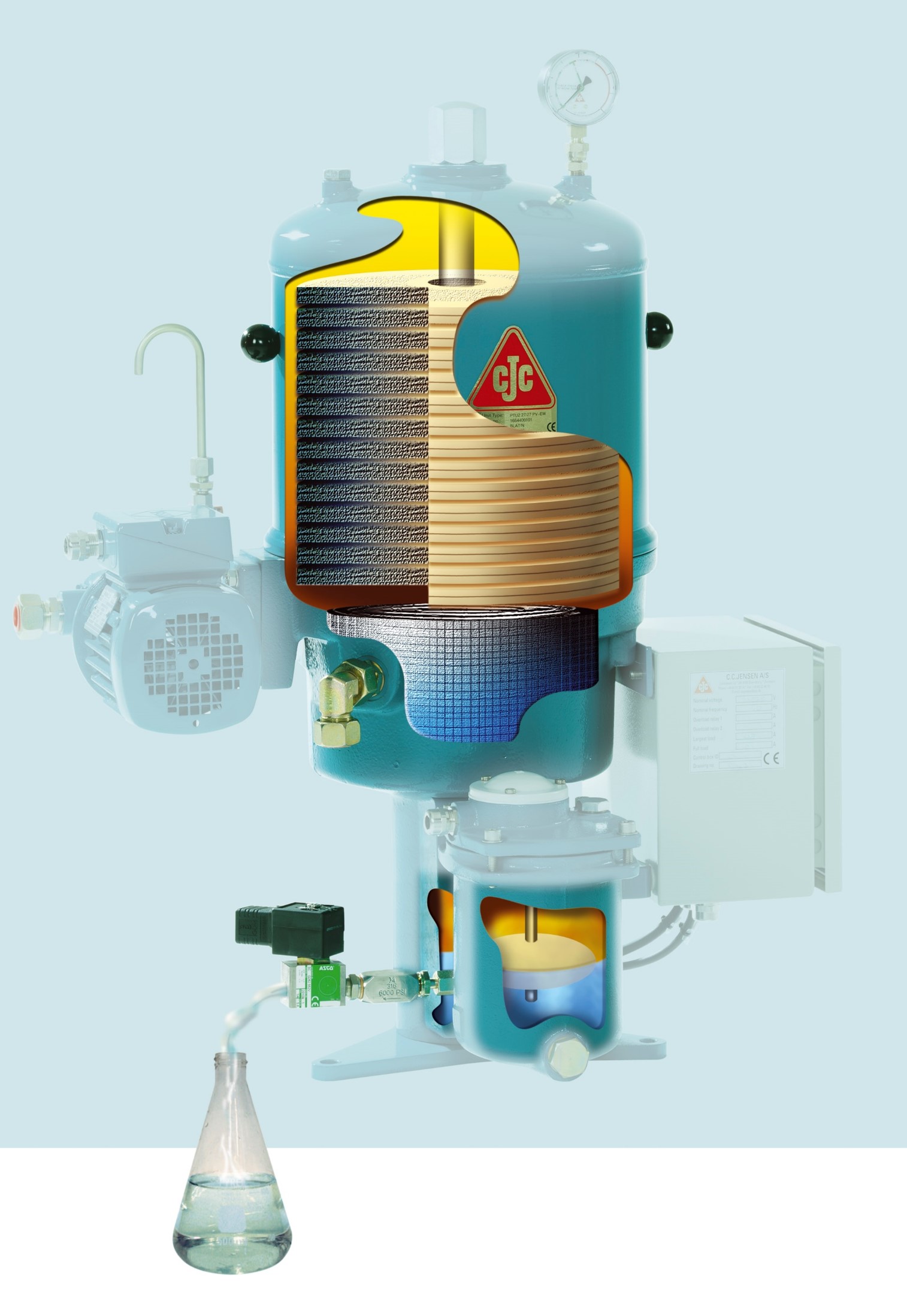

Offline Filter: A Solution

Offline filtration systems help reduce water in oil:

- Continuous Operation: These systems provide round-the-clock protection.

- Advanced Filtration: Technologies like coalescing filters efficiently separate water from oil.

- Increased Oil Life: Clean oil extends usable life, reducing maintenance costs.

- Enhanced Performance: Clean oil ensures optimal lubrication and reduces wear.

- Cost-Effective Maintenance: Offline systems are easy to maintain and integrate into existing setups.

Conclusion

Water contamination in oil leads to significant operational issues and costs. It reduces bearing life, depletes additives, and compromises machinery performance. Implementing offline filtration systems proactively manages water content, enhancing machinery longevity and efficiency, and providing substantial cost savings.