Contaminated Oil Leads To Premature Wear

Maintaining clean oil in machinery is essential to prevent premature wear. Contaminants like particles, moisture, acidity, chemicals and varnish act as abrasive agents, wearing down crucial components.

Solid particles cause abrasions, moisture and acidity leads to corrosion, and chemical contaminants degrade oil and surfaces. Varnish, a less visible but equally damaging contaminant, forms deposits hindering proper lubrication and causing increased friction and wear.

The consequences are costly, thus proactive maintenance with oil condition monitoring, effective filtration and optimal maintenance is crucial to ensure reliability and minimise downtime.

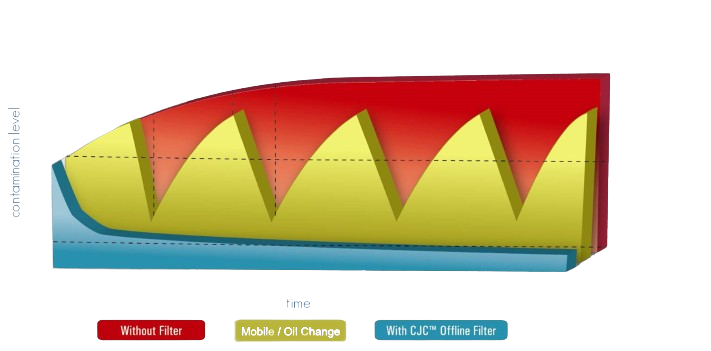

Regular oil changes alone are insufficient to prevent premature wear because contamination buildup occurs between changes, contributing to wear. Human error during maintenance, such as overfilling or underfilling the oil, using the wrong type of oil, or incorrectly installing the oil filter, can lead to engine damage or failure. Additionally, machines are exposed to contamination during maintenance procedures.

A highly recommended practice is to utilise a high-quality offline oil filter to ensure consistently clean oil, thus minimising wear on machinery. This approach also reduces disruptions caused by unnecessary oil changes. Significant savings can be achieved through reduced oil consumption, extended service intervals, and prevention of unexpected failures.