Contaminated Oil: The Silent Culprit Behind Unexpected Failures And Downtime

Oil contaminated with particles, moisture, and varnish quietly harms machinery, leading to sudden breakdowns and downtime. Solid particles erode essential parts, moisture triggers corrosion, and varnish hampers proper lubrication. These breakdowns catch operators off guard because they often occur without warning.

Moreover, excessive and unnecessary oil changes also contribute to downtime by interrupting operations and increasing the likelihood of mistakes during maintenance.

The consequences of contaminated oil and unnecessary oil changes are severe, causing unplanned downtime, delays, missed deadlines, lost revenue, and increased costs. Repairing damage and replacing parts require both time and resources, extending downtime and impacting customer satisfaction, contractual obligations, and business reputation.

To mitigate these risks, proactive and preventive measures such as oil condition monitoring, effective filtration, and optimal maintenance are crucial to ensure machinery reliability and minimise unexpected failures and downtime.

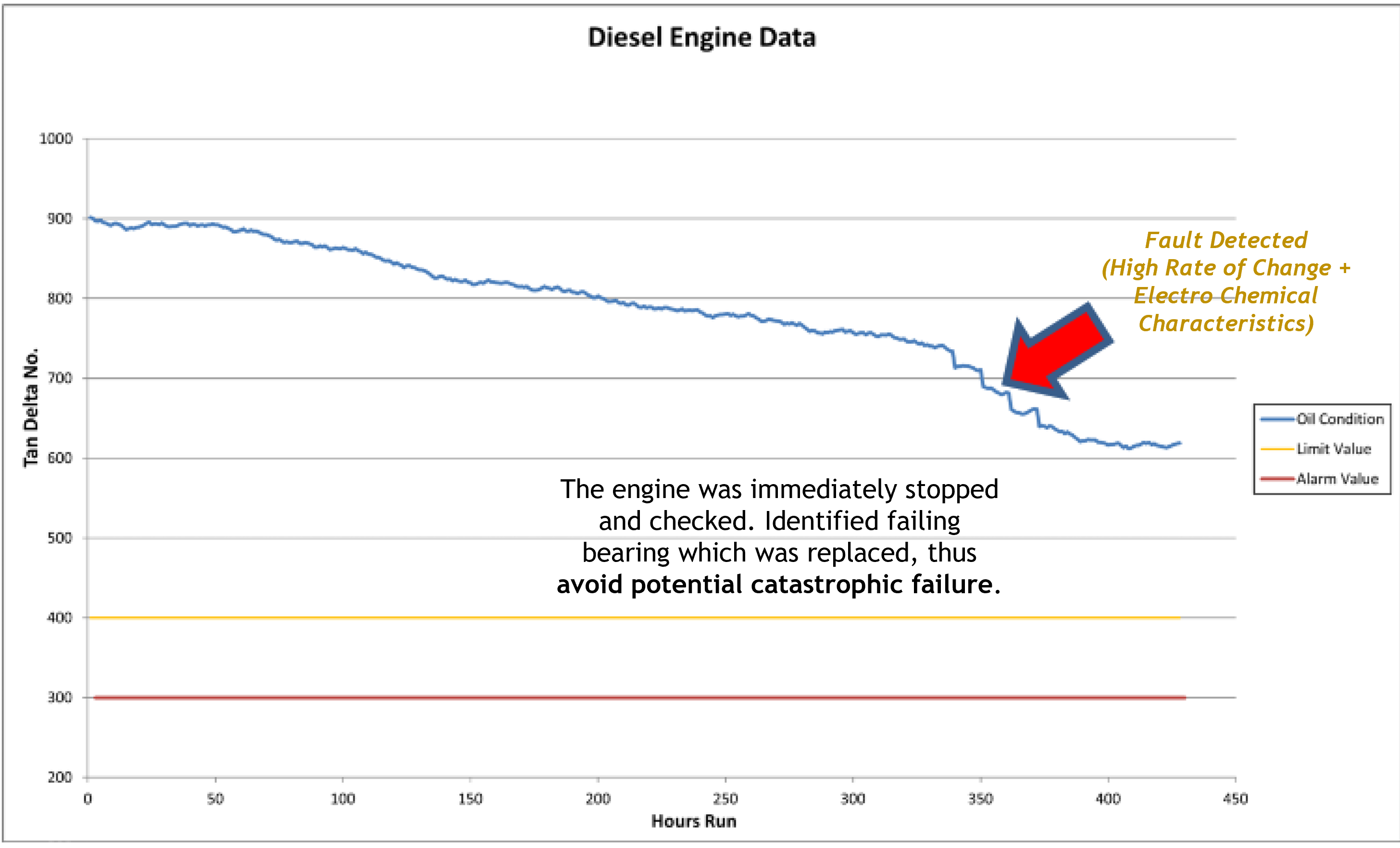

Using real-time oil condition monitoring to detect faults is a proactive approach to maintaining machinery health and preventing unexpected failures. This method involves continuously monitoring the quality and condition of the oil within the machinery, allowing for early detection of any abnormalities or signs of degradation. Benefits include early faults detection, facilitates predictive maintenance, optimised oil change intervals, cost savings, improved reliability, efficiency, and enhanced safety.