I have rewritten an article by Justin Stover of C.C. Jensen, who had wrote an informative article on how using an offline filter can save gearboxes from damage due to contaminated oil.

Dirt Contamination Causes 80% Of The Gearbox Damages

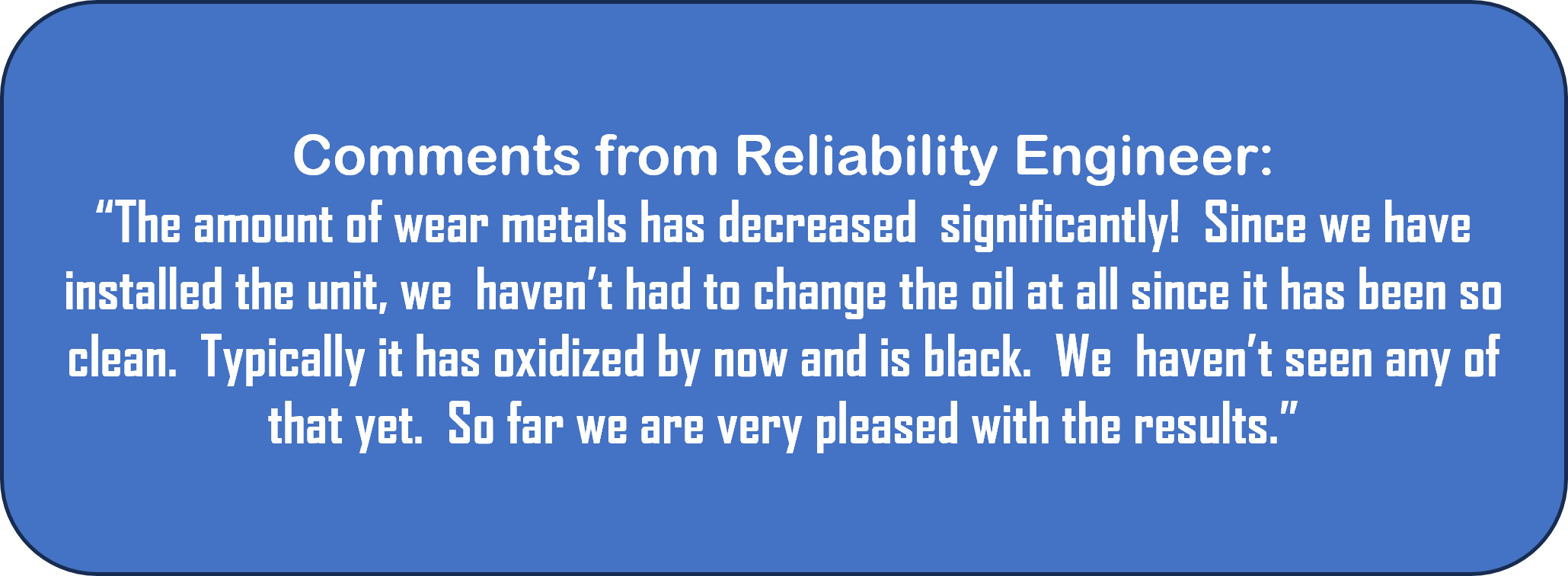

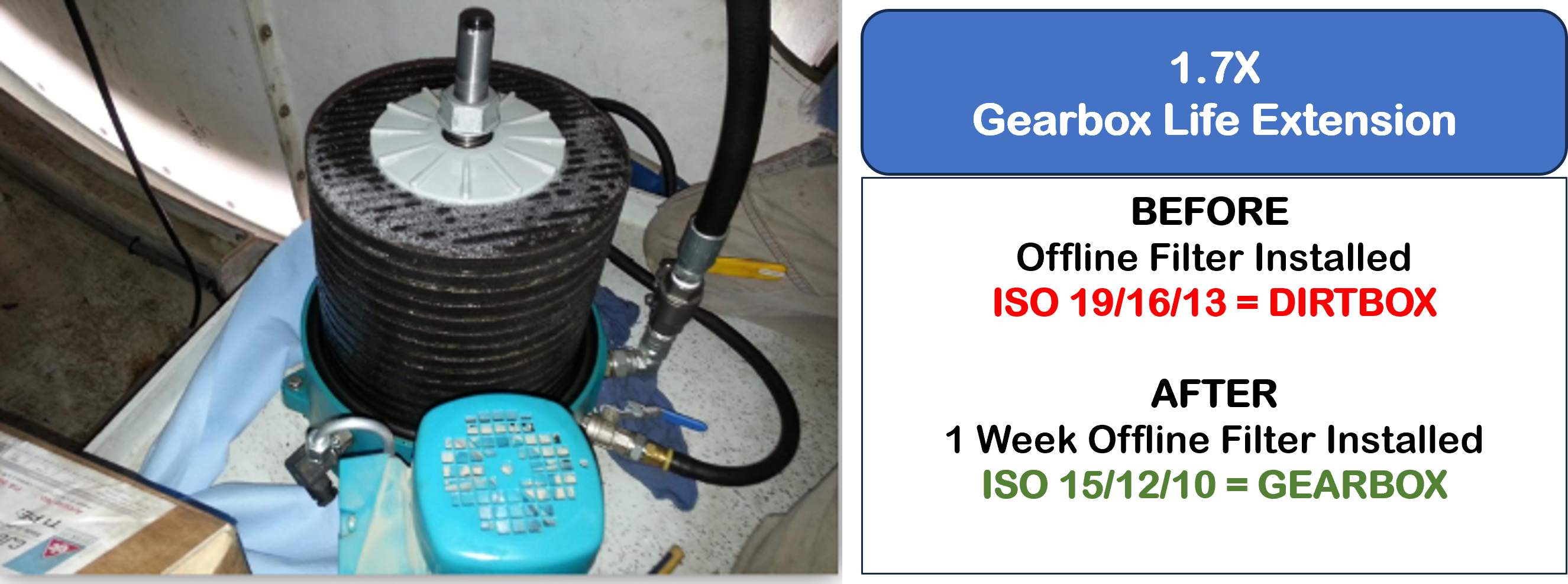

Dirty gearboxes don’t always require rebuilding, replacement, or running until failure. Nor does dirty gearbox oil have to be disposed of. Leading OEMs and savvy end-users have discovered that filtering oil with highly efficient offline filters can double or triple the life of gear oil and extend gearbox life by at least 50%.

Gearboxes represent incredible feats of engineering design. Gears and bearings smoothly glide on a microscopic layer of oil, invisible to the naked eye. This oil film, which separates gear teeth, is often just a few microns thick, making fine filtration essential for optimal performance.

Contamination in the form of dirt is unavoidable. It causes damage by indenting and abrading gear teeth, significantly reducing their lifespan. But where does this dirt originate? m? It is built-in during the manufacturing, assembly and run in process. Dirt is always a threat because it is internally generated, ingested and added during maintenance.

A gearbox containing 208 litres of oil and just half a teaspoon of fine dust will result in a particle count of approximately ISO 18/15/12. If the gearbox operates eight hours a day with a circulation rate of 60 litres of oil per minute, the gears would accumulate the equivalent of 11 kg of dirt over 200 days. With oil measuring ISO 20/17/14, the gears would accumulate 192 kg of dirt during the same period. Dirty gearboxes generate more dirt and increased wear.

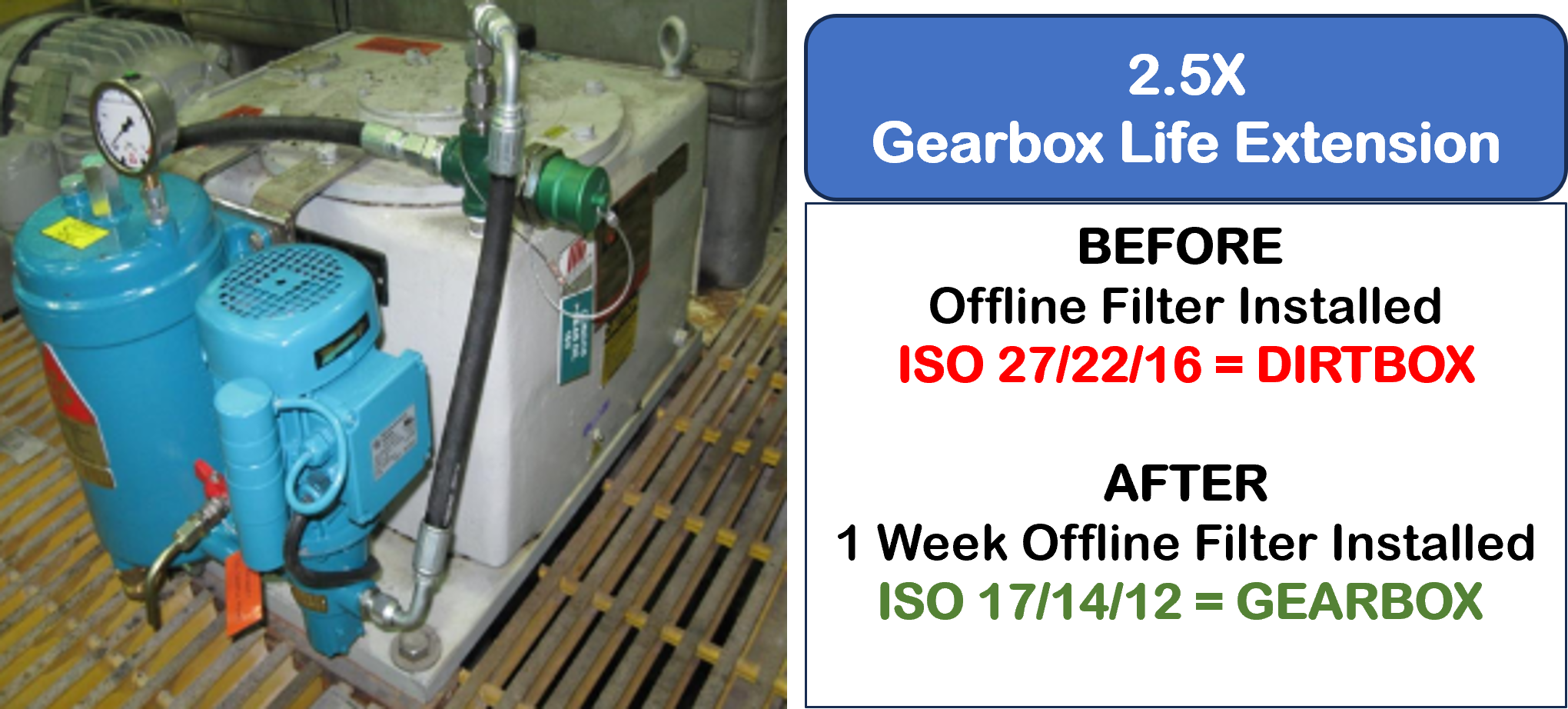

Due to excessive dirt accumulation, a dirty gearbox is sometimes referred to as a “DIRTBOX”.

What The Experts Says About Gearbox Filtration Using Offline Filter

“Offline filters provide fine filtration during operation and during shutdown. Once the oil is clean, it should stay clean provided the gearbox and lubrication system are properly designed and seals, breathers and maintenance are adequate.” – Robert Errichello and Jane Muller, GEARTECH

“When dirt particles in lubricating oils are considered, it is obvious that the cleaner the oil the better it is. This means that it always pays to keep the dirt content in the lubricant as low as possible.” – Bo O. Jacobson

FACT: No Gearbox Has Ever Failed Because the Oil was Too Clean!

A common concern is that “A fine filter will clog up very quickly.” However, this is actually a positive sign because it indicates the filter is doing exactly what it was designed to do – remove dirt. Upgrading filtration on a gearbox is neither difficult nor cost-prohibitive. Implementing this upgrade can make a substantial improvement to your business. Transitioning from a “Dirtbox” to a “Gearbox” enhances reliability and results in significant cost savings.

OEM’s and End Users are providing great stories about how they use Offline Filters on their Gearboxes. A common theme is that Offline Filters deliver amazing benefits. Here are a few examples.

CASE STUDY 1: Refinery “Dirtbox” Converted To A Refinery Gearbox Using Offline Filter

Global Mining and Metals Company

System: Refinery Gearbox that was routinely highly contaminated

Oil type: 16 Gallons (60 litres) ISO VG 150 cSt

Driven by a commitment to continuous improvement and sustainable practices, this End User ventured into exploring alternative methods and approaches to extending asset life. The aim was to add value and ultimately benefit the environment.

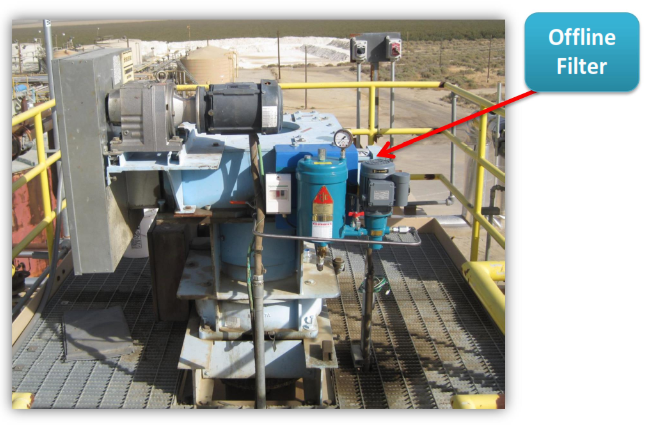

CASE STUDY 2: Rake “Dirtbox” Converted To A Rake Gearbox Using Offline Filter

Oil and Gas Producer

System: Rake Gearbox operating outdoors and heavily contaminated

Oil type: 12 Gallons (45 litres) ISO VG 680 cSt

CASE STUDY 3: Wind Turbine “Dirtbox” Converted To A Wind Turbine Gearbox Using Offline Filter

Wind Energy Company

System: 1.5 MW Wind Turbine Gearbox

Oil type: 80 Gallons (302 litres) ISO VG 320 cSt

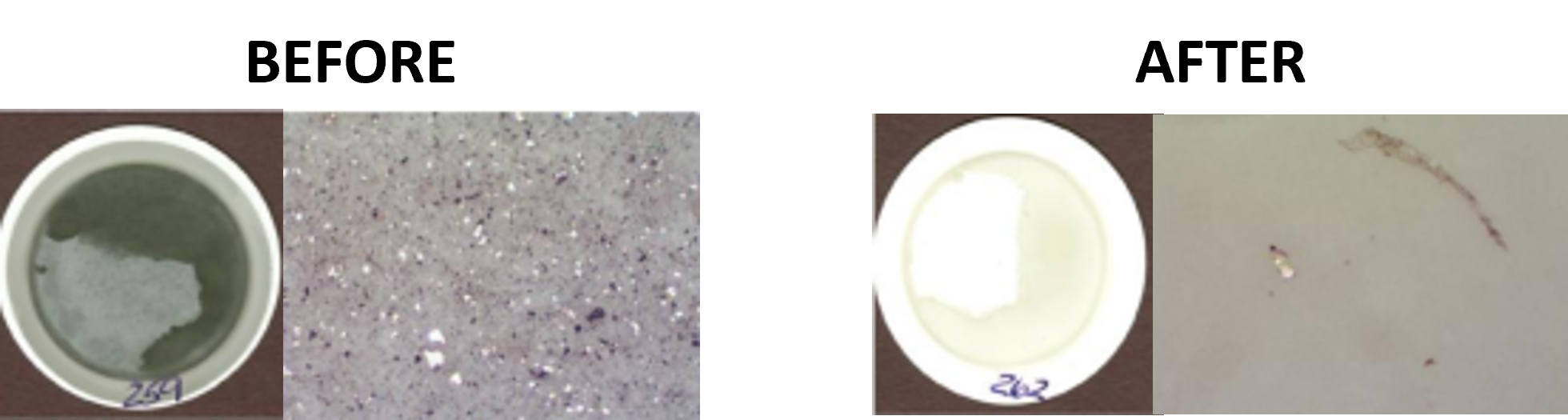

Results You Can See

(Patch Test and 100X Magnification)

How to Convert from a “Dirtbox” to a Gearbox

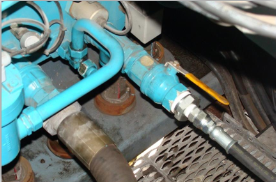

Step 1: Select a properly sized Offline Filter

Step 2: Identify a Mounting Location on or near the Gearbox

Step 3: Make the oil suction, oil return and electrical connections

Then, you are on your way to convert “Dirtbox” to Gearbox and avoid costly gearbox damage.